Gypsum, mined from nature, is crushed to the appropriate size for operations in plant. While crushers with proper installation creates on effective breaking process, pre-treatment of the gypsum powder in ERBA quality is completed smoothly. Gypsum is brought to 0-10 mm which is a maximum feed size for mill, in crushing-screening unit. These dimensions are sufficient for calcinations process.

Calcination Dryer is a rotary kiln and is manufactured by calculations and dimensioning in accordance with the request of our customers as per capacity of the factory. Calcination Unit consists of Feeding Bunker, Weighing Belt, Burner, Combustion Chamber, Mixture Section, Inlet-Outlet Hoods, Air Ducts, Cyclone, Fans and Transfer Units. Calcination unit is used in gypsum production factory to obtain gypsum, characterized as base gypsum, by decreasing moisture content, of crystal water (-20) existing in the gypsum rock, which is crushed to grain size of 0-10 mm, to a desired values (4-6%). During this process temperature in the Calcination unit is increased to 800-1200°C.

By means of a Feeding Bunker and Weighing Belt which are the first equipment of drying unit, the amount of product that is fed to the dryer is kept constant by adjusting the amount of product supplied to the dryer.

Required heat for system is produced by the Burner and Combustion Chamber. Desired amount of fuel and air can be controlled thanks to proportional control.

Both moving along the kiln line and blending are provided with specially designed star and wing system in dryer. Micronized products (max 200g/Nm3), moving by means of air flow in the system, are recovered thanks to Dryer Cyclone. Product (max. 50g/N m3) that is recycled to system are also provided in Filter.

Our dryers, length, diameter, required amount of air, filtration area ad interior structure, are designed according to engineering calculations depending on type of product and grain size. Rings, gears and gales varies according to filled load of dryer. They are brought to proper hardness with rendered heat treatment in benches after casting.

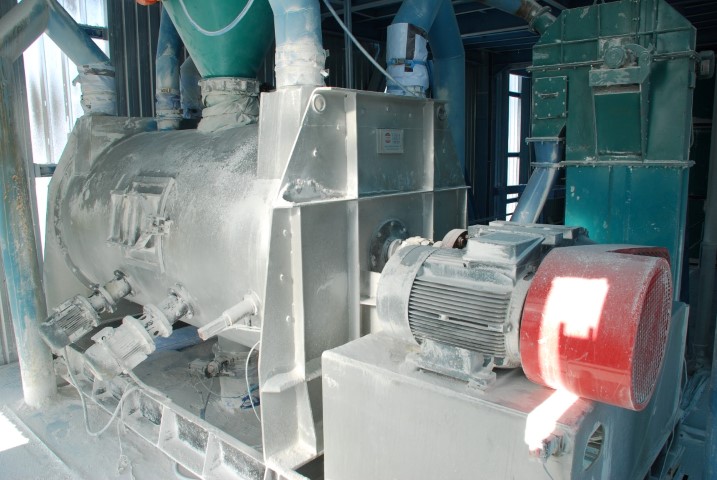

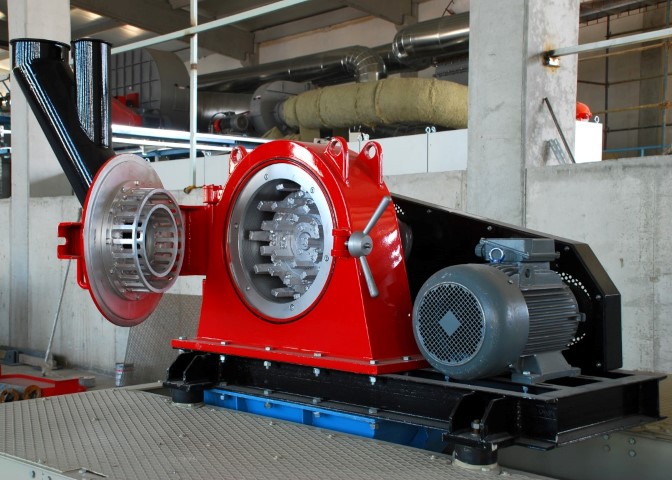

Centrifugal Hammer Mill is used for grinding the dry or slightly moist materials which has maximum feed size of 0-10 mm up to 1000 microns.

Grinding is provided by the crushing force from rotating high speed hammers applied to the ore. Capacity for an hour can reach up to 50 tons. It allows significant energy savings so only rotor which has hammers is rotates.

This mill provides low maintenance costs and high performance. It is an ideal machine if the final preparation is desired to have high specified gravity.

Produced mills with advanced technology and all our products are precision, long life, high capacity, secure and has a minimum energy consumption. Grinded gypsum powder pass through air separators. The semi-finished products divided into fine and coarse types. Separator Unit consists of blower, fan, filter and a cyclone.

All transportation operations, both vertical and horizontal, in our factories are performed through Bucket Elevators, Belt Conveyors, Roller Conveyors and Screw Conveyors. All the machines located in factories built by ERBA, are projected with top-level engineering calculations. All equipment and materials are certified in accordance with European Standards.

Mixing unit provides homogeneous mixing according to the produced product type. Its design and technology is very important for top-quality plaster production. Capacities of the mixing units are decided as per plants capacity.

Packing units of gypsum plants might be linear type or rotary type depending on the plant capacity and product types.